Electric wires play a crucial role in modern society. They are essential for powering homes and businesses. According to Jane Smith, an expert in the Electric Wire industry, "Understanding the types of electric wire can help prevent electrical hazards." Her insight highlights the importance of knowing your wire options.

There are various types of electric wires, each designed for specific applications. The most common types include NM cable, THHN wire, and UF wire. These wires differ in insulation, materials, and uses. For example, NM cable is ideal for indoor use in residential wiring. This specificity often leads to confusion, especially among DIY enthusiasts.

Despite clear classifications, mistakes can happen. Choosing the wrong wire could lead to short circuits or even fires. It’s vital to familiarize oneself with the characteristics of different wires. Being informed can minimize risks and enhance safety. Electric wire selection isn’t just technical; it's about protecting lives and property.

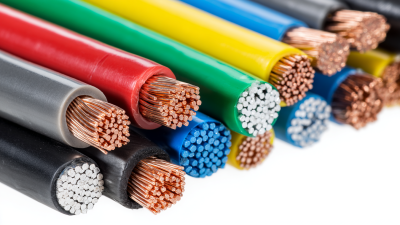

When exploring types of electric wire, it's crucial to recognize their unique functions. Two common types are copper and aluminum wire. Copper wire is known for its excellent conductivity. It’s often used in residential wiring. On the other hand, aluminum wire is lighter and more affordable. However, it can be less reliable in certain applications.

Another essential type is armored cable. This wire is encased in a protective layer. It is ideal for installations in areas prone to physical damage. Then, there's the low-voltage wire. It provides power for outdoor lighting and security systems. These applications show how a minor choice can impact overall safety and efficiency.

Understanding these wires helps in making informed decisions. Yet, many overlook wire specifications when planning projects. This can lead to safety hazards or electrical failures. It's crucial to reflect on these details. Selecting the right type of wire can significantly enhance performance and ensure safety.

| Type of Wire | Uses | Insulation Type |

|---|---|---|

| Non-metallic Sheathed Cable (NM) | Residential wiring for outlets, switches, and lighting | Plastic insulation, typically PVC |

| Thhn/Thwn Wire | Indoor and outdoor applications; commercial and industrial wiring | Thermoplastic insulation |

| Romex | Typical household wiring for insulation and low wiring | Non-metallic sheath |

| Coaxial Cable | Television and internet signals | Braided copper shield and plastic insulation |

| Armored Cable (AC) | Used in environments where physical damage is possible | Metal protective sheath |

| Service Entrance Cable (SEC) | Main electrical service line from the pole to the meter | Heavy-duty insulation, usually in a flat configuration |

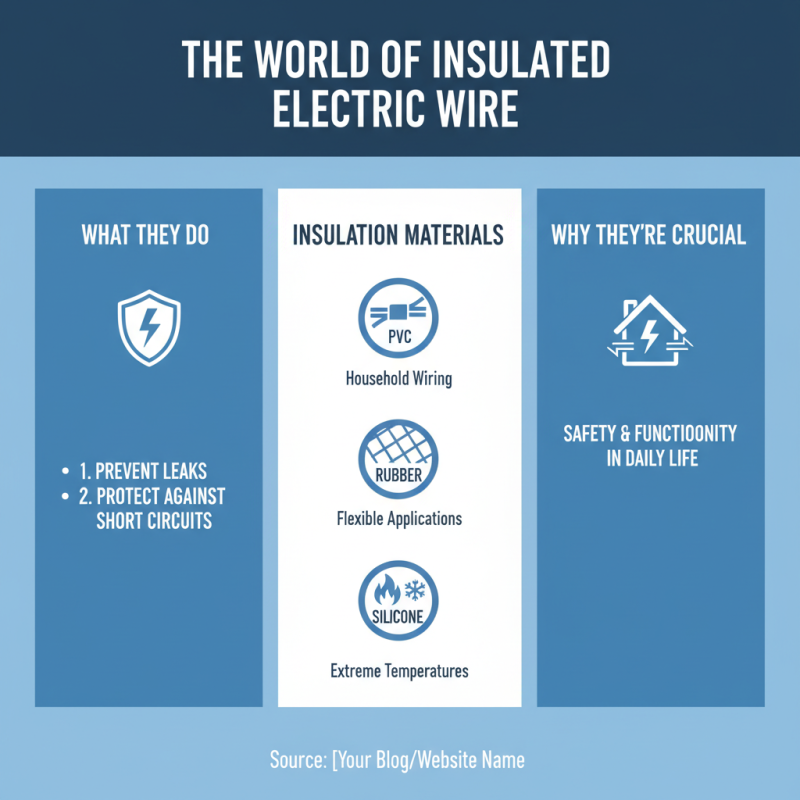

Electric wire comes in various types, each serving unique purposes in our daily lives. Insulated wires are vital for safety and functionality. They prevent electrical leaks and protect from short circuits. Insulation materials vary, including PVC, rubber, and silicone. Each has distinct properties for different environments. For example, PVC is common in household wiring, while silicone works better in extreme temperatures.

Understanding how to choose insulated wire is essential. Not all wires are suitable for high-voltage applications. Some wires might be too fragile for outdoor use. It's critical to consider the insulation properties. A wire with insufficient insulation can lead to dangerous situations. Always check for wear and tear, especially in older installations.

Using the wrong type of insulated wire can lead to performance issues. You may notice frequent outages or device failures. Some wires may not withstand humidity or corrosion. Look for signs of damage or degradation over time. It’s important to reflect on the selection process and ask questions. Proper research can prevent costly mistakes. Make sure you understand the specific needs of your project.

Non-insulated wires play a crucial role in various electrical systems. They are often used in environments where insulation may not be necessary. For instance, many industrial applications favor non-insulated wires due to their ability to handle high currents and their reduced cost. According to a report by the International Electrotechnical Commission, around 40% of industrial setups utilize non-insulated conductors for specific tasks.

These wires are commonly found in overhead power lines and grounding systems. In overhead lines, non-insulated wires provide excellent conductivity. They can endure harsh weather while ensuring reliability in power distribution. In grounding systems, these wires safeguard equipment from electrical surges. However, improper installation can lead to safety hazards. While non-insulated wires are efficient, they require careful handling.

The application of non-insulated wires is not without challenges. They demand precise installation techniques to prevent short circuits. Data from the National Electric Code indicates that about 15% of electrical failures stem from improper wire usage in grounding applications. This highlights the importance of proper training and adherence to safety standards when dealing with non-insulated wires. Mistakes in their application can lead to significant risks, emphasizing the need for caution.

Specialty wires play a crucial role in modern electrical installations. They are designed for specific purposes, ensuring safety and efficiency. For example, high-temperature wires can withstand extreme conditions. This is vital in industrial settings, where heat can compromise standard wiring.

Data from the National Electrical Manufacturers Association (NEMA) shows that specialty wires constitute about 20% of the electrical wire market. This segment is growing, driven by advancements in technology. Specialty wires, such as those used for renewable energy systems, are gaining traction. These wires are essential for solar and wind energy applications. They need to endure different elements and environmental conditions.

Another area of importance is medical wiring. In hospitals, specialized cabling is essential for life-saving equipment. The choice of wire can impact patient safety and treatment outcomes. Some installations use multi-stranded cables for flexibility and reliability. However, there are pitfalls. Installation errors can lead to malfunctions. Ensuring the correct application of specialty wires is critical yet often overlooked. Proper training and awareness are vital for preventing issues in these specialized applications.

When working with electric wire, safety standards are crucial. Different types of wires have specific regulations. These standards help prevent accidents and ensure proper function. For example, there are guidelines for residential wiring. These rules cover the type of insulation used, wire gauge, and installation practices.

Compliance with safety codes is not just optional. Ignoring these can lead to dangerous consequences. Many people undervalue the importance of proper installation. Poor connections can create heat, leading to fires. This highlights the need for skill and training in electrical work.

Each wire type, whether it's THHN, NM, or UF, comes with its own set of guidelines. The environment plays a role too. Outdoor wires must withstand moisture and temperature changes. Using the wrong type can lead to system failures. It's a constant reminder that, while wiring may seem straightforward, the details matter significantly. Safety should always be the top priority when choosing and installing electric wire.