As we move towards 2025, the electrical industry is poised for significant advancements driven by technological innovations and evolving standards. A recent report by the International Electrical and Electronics Engineers (IEEE) highlights that the global market for electric wire and cable is projected to reach $200 billion by 2025, fueled by increasing infrastructure development and demand for renewable energy sources.

Choosing the right electric wire for your electrical projects has never been more crucial, as the right selection not only ensures safety and efficiency but also impacts overall project costs and sustainability goals. This ultimate guide will help you navigate the complex landscape of electric wire options, empowering you to make informed decisions that align with the latest industry trends and standards.

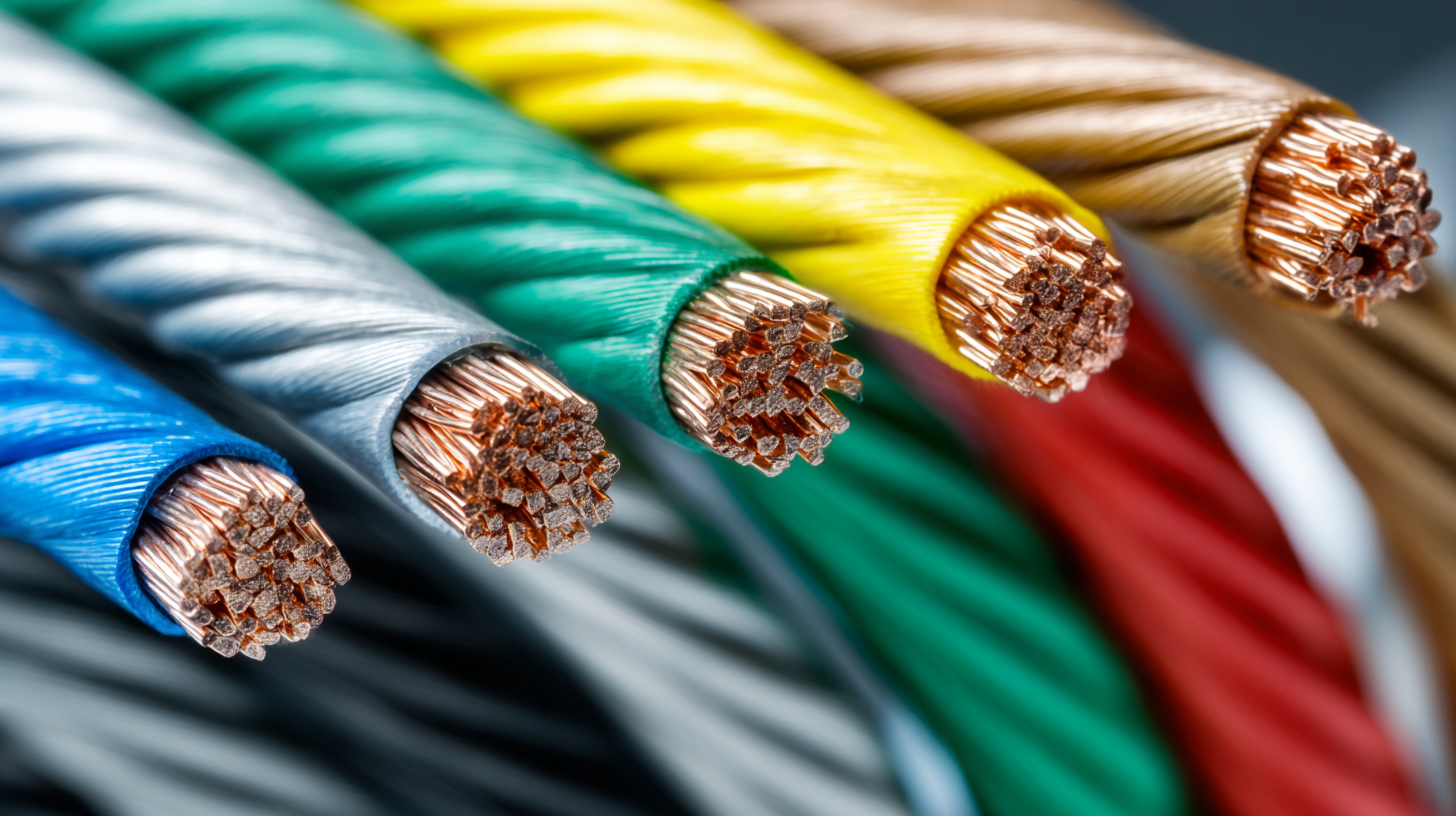

When it comes to electrical projects, the choice of wire is crucial for ensuring efficiency and safety. Copper wire stands out as one of the best options available, primarily due to its superior conductivity. With a lower resistance than other materials, such as aluminum, copper allows electricity to flow more freely, minimizing energy loss and increasing the overall performance of your electrical systems. This characteristic is especially important in applications where power demands are high, as it can lead to reduced heating and a lower risk of fire hazards.

Moreover, copper's excellent conductivity contributes to a longer lifespan for electrical projects. This durability means fewer maintenance issues and less frequent replacements, providing both time and cost savings. Additionally, copper wires are more flexible than their counterparts, making them easier to work with and install in various setups. Their corrosion resistance further enhances their longevity, making copper the go-to choice for both professional electricians and DIY enthusiasts aiming for high-quality results in their projects.

When considering electrical projects, aluminum wire stands out as a cost-effective solution. Aluminum, being lighter and often less expensive than copper, makes it an attractive option for various applications. Its excellent conductivity ensures efficient power delivery, while its resistance to corrosion contributes to long-term durability. Moreover, for large-scale installations, the substantial difference in cost can translate into significant savings.

Tip: When working with aluminum wire, it’s essential to use appropriate connectors and fittings designed for aluminum. This prevents potential overheating and enhances the overall safety of your electrical system.

Additionally, aluminum wire can handle higher loads, making it suitable for outdoor wiring and large appliances. Proper installation techniques are crucial; it’s advisable to follow the manufacturer's guidelines for splicing and securing.

Tip: Always verify local building codes and regulations before starting your project, as these may impact the choice of wire and installation methods. With careful planning and adherence to safety standards, aluminum wire can be a smart choice for your electrical needs.

When embarking on electrical projects, understanding wire gauge is crucial for ensuring both efficiency and safety. The gauge of the wire determines its current-carrying capacity and resistance, which greatly influences how well your electrical system performs. Thicker wires (lower gauge numbers) can carry more electrical current, which reduces the risk of overheating and fire hazards. On the other hand, using a wire that is too thin for your application's demands can lead to excessive energy loss and potential equipment damage.

**Tip:** Always consult the National Electrical Code (NEC) guidelines or a professional electrician to select the appropriate wire gauge for your specific project requirements. This proactive approach can help you avoid costly mistakes and ensure compliance with safety standards.

Another important aspect to consider is the length of the wire run. Longer distances can lead to voltage drop, which can affect the performance of your devices. If the wire run is significantly long, consider using a larger gauge wire to maintain optimal voltage levels at the appliance or device end.

**Tip:** For long runs, calculate the voltage drop and select a wire gauge that compensates for that loss. Tools and online calculators can help you determine the necessary gauge based on the distance and load, ensuring your project runs smoothly and safely.

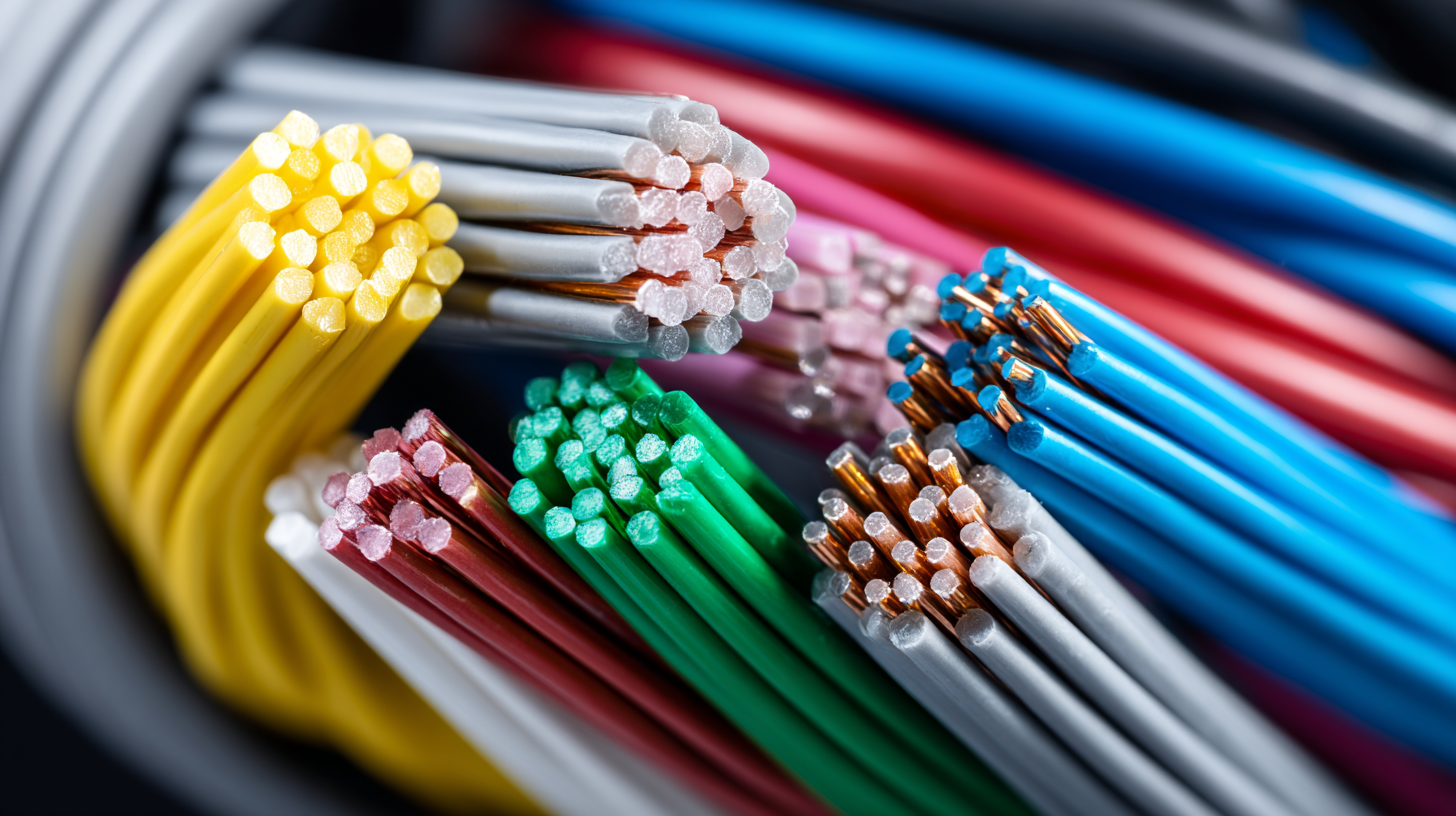

When selecting electric wire for your projects, considering the jacket material is crucial to ensure optimal durability and performance. Different jacket materials offer unique benefits:

PVC is common for its affordability and flexibility, while XLPE provides superior heat resistance and is ideal for high-temperature applications. Additionally,

rubber jackets are known for their excellent resistance to abrasion and impact, making them suitable for outdoor use where exposure to elements is a concern.

Tip: Always verify the environmental conditions where the wire will be used. For indoor installations, a standard PVC jacket might suffice, but for outdoor environments, consider investing in wires with UV-resistant jackets to prevent degradation over time.

A wire’s longevity also depends on its ability to withstand various physical stresses. Nylon and thermoplastic elastomer (TPE) jackets can provide an extra layer of protection against chemicals and moisture, making them perfect for industries where exposure to harsh substances is likely.

Tip: Check industry ratings for jacket materials to ensure they meet the specific needs of your project, especially when working with potentially corrosive environments or high traffic areas where wear and tear can occur more rapidly.

When it comes to electrical safety, the role of insulation types cannot be overstated. Insulation serves as the first line of defense against electrical hazards such as short circuits and electrical fires. According to the National Fire Protection Association (NFPA), electrical failures or malfunctions are responsible for nearly 24% of all residential fires in the United States. Selecting the appropriate insulation material can mitigate these risks significantly, ensuring both safety and efficiency in electrical projects.

Different insulation types offer varying degrees of protection and performance. For instance, thermoplastic insulation materials, such as PVC, are widely used due to their excellent resistance to moisture and chemicals, making them ideal for indoor installations. On the other hand, XLPE (cross-linked polyethylene) insulation is gaining popularity for its superior thermal stability and higher dielectric strength, making it suitable for high-voltage applications. A report from the International Electrotechnical Commission (IEC) indicates that using high-grade insulation can reduce energy losses by up to 15%, proving that insulation not only enhances safety but also contributes to long-term energy efficiency in electrical systems.

This chart illustrates the thermal resistance of various insulation types used in electric wires. Each type has a specific temperature rating, which is crucial for preventing electrical hazards and ensuring optimal performance in different environments.