In the world of global procurement, selecting the right components is crucial for the success of any electrical project, and electric wire is at the forefront of this selection process. With a myriad of options available, from material types to insulation ratings, mastering electric wire selection can significantly impact product performance, safety, and compliance with international standards. This blog will explore effective solutions for navigating the complexities of electric wire selection, considering factors such as application requirements, environmental conditions, and regulatory compliance. By understanding these essential elements, procurement professionals can streamline their decision-making process, ensuring that their projects not only meet but exceed expectations. Join us as we delve into this critical aspect of industrial sourcing, equipping you with the knowledge to enhance your global procurement strategy.

When it comes to procuring electric wire on a global scale, understanding the diverse standards that govern wire specifications is crucial. Different countries may have distinct regulations, and compliance with these standards ensures safety, reliability, and compatibility of electrical installations. For instance, the International Electrotechnical Commission (IEC) outlines standards like IEC 60228 for conductors, while the National Electrical Code (NEC) in the United States has its own set of guidelines. According to a report by Allied Market Research, the global electric wire and cable market size was valued at $193 billion in 2020 and is projected to reach $250 billion by 2027. This upward trend highlights the importance of understanding regional standards to maintain a competitive edge.

Additionally, issues such as voltage requirements and temperature ratings vary widely across regions. The European Union's Low Voltage Directive and the UL standards in North America set stringent criteria for performance and safety, impacting the design and procurement of electric wires. A comprehensive analysis from ResearchAndMarkets indicates that the demand for insulated wire is expected to grow at a CAGR of over 6% between 2021 and 2026. Buyers should not only focus on the cost but also integrate knowledge of local certifications and compliance to avoid costly delays and ensure project success across different markets.

| Wire Type | Conductor Material | Insulation Type | Voltage Rating (V) | Application |

|---|---|---|---|---|

| THHN | Copper | PVC | 600 | General Purpose Wiring |

| NM-B | Copper | Thermoplastic | 300 | Residential Wiring |

| XHHW | Aluminum | Cross-Linked Polyethylene | 600 | Industrial Applications |

| UF-B | Copper | Thermoplastic | 600 | Underground Feeder |

| SEU | Copper | Thermoplastic | 600 | Service Entrance |

When selecting electric wire for international markets, several key factors must be considered to meet the diverse needs of global procurement.

Firstly, understanding regional regulations and standards is crucial. Each market may have specific electrical codes and safety requirements that dictate the type of materials and construction methods permitted. Adhering to these regulations ensures compliance and reduces the risk of legal issues or product recalls.

Additionally, market growth trends indicate a significant evolution in the electrical equipment sector. For instance, the global wire and cable materials market is projected to expand from approximately $173.52 billion in 2025 to $244.44 billion by 2032. This growth trajectory highlights the importance of anticipating future demands, which may include a rise in renewable energy projects and electric vehicle infrastructure. Choosing the right type of wire, such as fire-resistant or specialized solar cables, can cater to the increasing focus on sustainability and safety in electrical systems globally. These decisions not only enhance operational efficiency but also position companies strategically within competitive international markets.

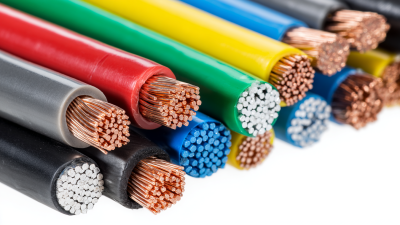

When it comes to wire procurement, evaluating quality and compliance is paramount. The first key metric to consider is the wire's material. Different applications require specific types of wire, such as copper for its conductivity or aluminum for its lightweight properties. Analyzing the material not only impacts performance but also affects compliance with international standards and regulations, ensuring that the wire meets the necessary safety and operational requirements.

Another essential metric is the wire's insulation and temperature rating. Proper insulation is crucial for protecting the wire from environmental factors and preventing electrical failures. Additionally, understanding the temperature ratings helps in selecting wires that can withstand the operational conditions of their intended use. This consideration is vital for global procurement as different regions may have varying environmental challenges and compliance rules. By carefully evaluating these metrics, organizations can make informed decisions, ensuring they procure not just any wire, but the right wire that adheres to global compliance and quality standards.

Emerging technologies in electric wire manufacturing are significantly shaping the future of global procurement. As industries evolve, the incorporation of advanced materials and smart manufacturing processes is becoming increasingly critical. For example, the latest reports indicate that the global electric wire and cable market is projected to reach approximately $250 billion by 2025, driven by innovations such as wireless power transfer and enhanced energy efficiency standards. These advancements not only streamline manufacturing but also align with the growing demand for sustainable energy solutions in various sectors.

Moreover, trends like the rise of electric vehicles (EVs) and microgrid systems further emphasize the need for specialized electric wires that can support higher energy loads and improved performance. A survey from industry experts predicts that the EV market alone will drive a 50% increase in the demand for specific wire types by 2030. As companies prioritize smarter, more efficient technologies, the electric wire selection process becomes paramount to meet both regulatory standards and consumer expectations. The ongoing advancements in battery technology and the integration of artificial intelligence into energy systems are also expected to play a transformative role in optimizing electric wire design and applications.

The growing focus on renewable energy sources such as solar, wind, and hydropower is significantly influencing the demand for electric wires in global procurement. As the shift toward sustainable practices accelerates, the electric wire market experiences a transformation driven by the need for energy-efficient and environmentally friendly solutions. According to industry reports, the demand for copper—a key component in many electric wires—is projected to increase as markets adopt renewable technologies, with a particular emphasis on innovations in sustainable mining practices to support this trend.

Moreover, the integration of Industry 4.0 technologies into supply chains is facilitating smarter sourcing strategies. With advancements in artificial intelligence and the Industrial Internet of Things (IIoT), companies can optimize supplier selection, enhance inventory control, and improve production efficiency. This evolution not only leads to cost savings but also aligns with eco-friendly initiatives and the circular economy principles. As global supply chains adapt to these sustainable trends, the emphasis on sourcing electric wires will increasingly reflect the urgent need for responsible and efficient procurement practices.