In the ever-evolving world of construction, choosing the right types of electrical cables is paramount for ensuring the safety and efficiency of any project. As we approach 2025, industry experts emphasize the importance of staying ahead with innovative solutions. According to John Smith, a renowned electrical engineering expert, "The right choice of electrical cable can significantly impact the longevity and performance of electrical systems in modern buildings." This statement underscores the critical nature of making informed decisions when selecting electrical cables.

As construction projects become more complex, the need for reliable and high-quality electrical cables grows. With advancements in technology, the range of cables available is wider than ever, offering options suited for various applications and environments. Whether it’s for residential, commercial, or industrial projects, understanding the different types of electrical cables is essential for compliance and efficiency.

In this context, it is vital to consider factors such as the cable's material, insulation type, and its specific application. By exploring the top electrical cable types recommended for 2025, construction professionals can ensure they meet both current and future demands of the industry, ultimately contributing to safer and more sustainable developments.

When it comes to electrical installations in construction projects, selecting the appropriate type of cable is crucial for safety and efficiency. The most common types of electrical cables used in construction include NM cable, also known as Romex, which is widely favored for residential buildings due to its lightweight and ease of installation. Additionally, THHN wire is often employed in commercial settings, where durability and heat resistance are paramount, making it suitable for conduit systems.

Another popular option is the UF cable, which is designed for underground use, providing protection against moisture and environmental factors. For outdoor installations, it's essential to consider cables rated for wet locations, which have superior insulation properties. When working on larger construction projects, the use of armored cables can provide extra durability and protection against physical damage.

Tips: Always check local building codes and regulations when selecting electrical cables, as they can vary significantly. Proper labeling and organization during installation can save time and reduce errors. Additionally, ensure that all cables are adequately rated for the specific load and environmental conditions they will face, as this can significantly impact the overall performance and safety of the electrical system.

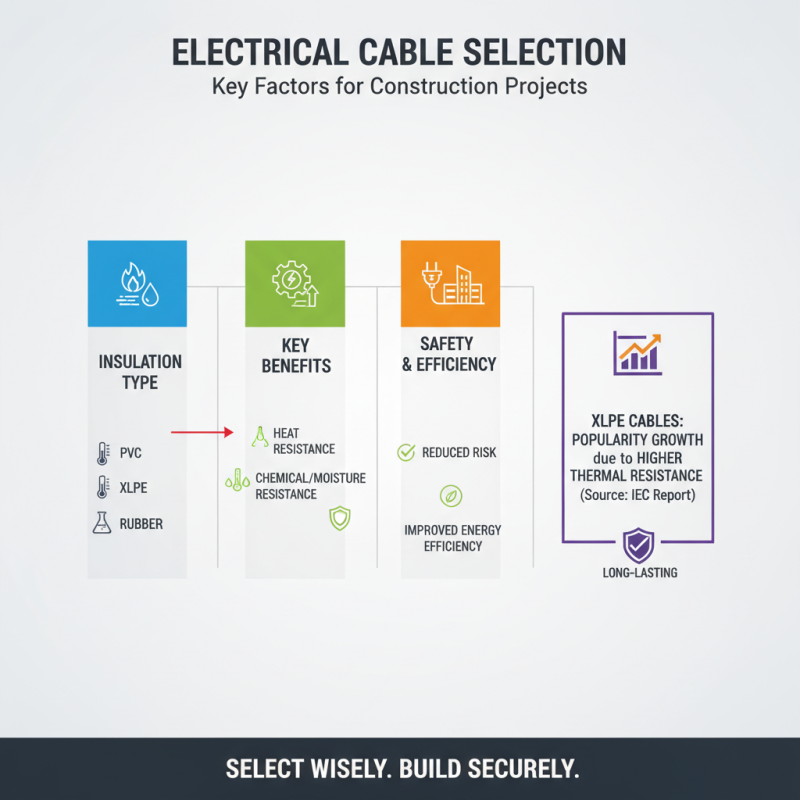

When selecting electrical cables for your construction projects, several key factors play a crucial role in ensuring safety, efficiency, and longevity. The first consideration is the type of insulation material. Common options include PVC, XLPE, and rubber, each offering different levels of resistance to heat, chemicals, and moisture. According to a report by the International Electrotechnical Commission, XLPE cables are gaining popularity due to their higher thermal resistance, which can improve energy efficiency and reduce the risk of electrical failures.

Another important factor is the cable's conductor material, typically copper or aluminum. While copper boasts excellent conductivity and is preferred for its reliability, aluminum cables are often chosen for their lower weight and cost-effectiveness. The National Electrical Manufacturers Association (NEMA) highlights that aluminum conductors can be up to 30% lighter than copper, making them advantageous for large-scale projects where weight, especially in overhead installations, is a concern.

Lastly, the application environment should greatly influence your cable selection. For instance, cables intended for outdoor use must have UV-resistant and weatherproof features, while those designed for industrial settings might require additional shielding against electromagnetic interference. A report by the International Energy Agency suggests that proper cable selection can reduce energy loss by up to 15%, emphasizing the financial and operational benefits of making informed decisions based on the specific requirements of each project.

When considering electrical cable options for construction projects in 2025, a key debate revolves around the choice between copper and aluminum cables. Copper wires have long been favored for their superior conductivity, making them ideal for demanding electrical applications. They boast lower resistance, which leads to less energy loss and greater efficiency in power transmission. Additionally, copper is known for its durability and resistance to corrosion, lending itself to enhanced longevity in various environments. This makes copper cables a reliable choice, particularly for high-load and critical systems.

On the other hand, aluminum cables present a compelling alternative, especially in cost-sensitive projects. Although aluminum has a lower conductivity than copper, advancements in technology have allowed for the development of larger diameter aluminum cables that can match the performance of their copper counterparts. They are lighter and more flexible, making installation easier and reducing support structure requirements. Furthermore, aluminum cables are generally less expensive than copper, contributing to reduced overall project costs. It's essential for project managers to evaluate the specific requirements of their electrical systems when choosing between these two materials, as each offers unique benefits suited to different applications.

This chart presents a comparison of key properties of copper and aluminum electrical cables relevant for construction projects in 2025.

When planning for construction projects in 2025, selecting the right type of electrical cable is crucial to ensure safety, efficiency, and compliance with industry standards. Specialized electrical cables serve different purposes in various construction applications, and understanding these differences can greatly enhance the overall performance of electrical systems. For example, in commercial buildings where high-capacity electrical systems are required, armored cables made from steel or aluminum may be used to provide extra protection against physical damage. According to the National Electrical Manufacturers Association (NEMA), the demand for these robust cables is projected to grow by approximately 5% annually through 2026, driven by increasing urbanization and infrastructure development needs.

Additionally, for residential applications, low-voltage cables are gaining popularity. These cables, including data and communication lines, are essential for integrating smart home technologies that provide convenience and energy efficiency. A report from MarketsandMarkets suggests that the low-voltage electrical cable market is anticipated to reach USD 15.5 billion by 2025, highlighting the shifting focus towards modernization in home construction. Moreover, in industrial settings, cables such as thermoplastic elastomer (TPE) insulated cables are recommended for their flexibility and resistance to extreme temperatures, catering to environments with harsh operating conditions. Investing in the right type of specialized electrical cables tailored to specific construction applications ensures reliable performance and longevity of electrical infrastructures in upcoming projects.

| Cable Type | Application | Conductor Material | Insulation Type | Typical Uses |

|---|---|---|---|---|

| THHN Wire | General wiring | Copper | PVC | Residential and commercial buildings |

| XHHW Wire | High heat applications | Aluminum | Cross-linked polyethylene | Commercial and industrial projects |

| MC Cable | Multi-conductor wiring | Copper | PVC | Lighting circuits and branch circuits |

| UF Cable | Underground applications | Copper | PVC | Outdoor lighting and garden projects |

| Fiber Optic Cable | Data transmission | N/A | Various polymer materials | Networking and telecommunications |

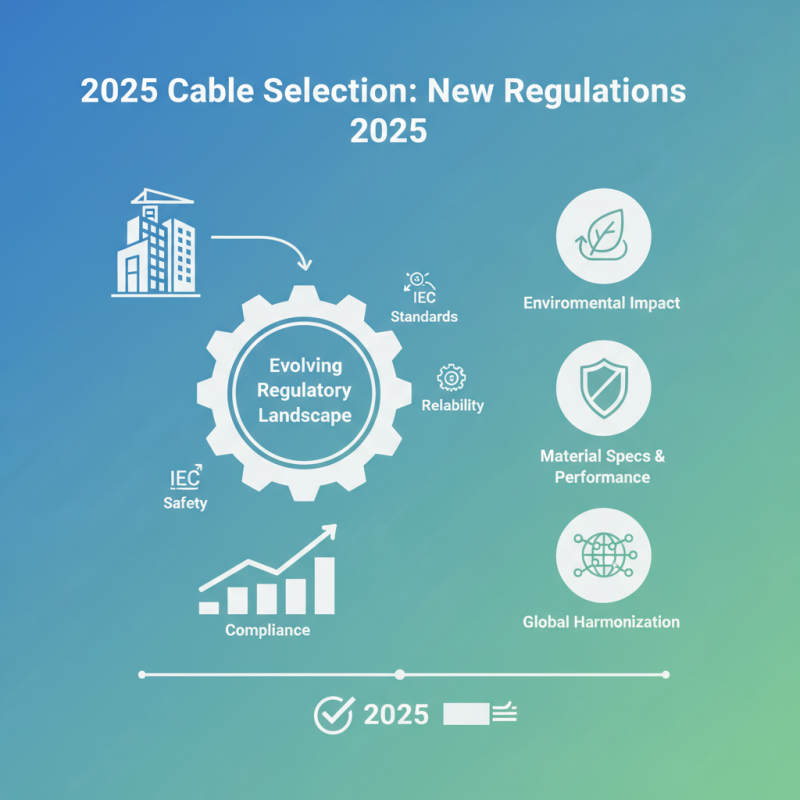

In 2025, the selection of electrical cables for construction projects will be significantly influenced by the evolving regulatory landscape. Recent data from the International Electrotechnical Commission (IEC) indicates that compliance with stringent standards will be imperative to ensure safety and reliability in electrical installations. These regulations encompass a wide variety of factors, including material specifications, environmental impact criteria, and performance metrics under different conditions, which are essential for harmonizing global practices.

One of the most critical changes expected is the tightening of fire safety standards, as indicated by a report from the National Fire Protection Association (NFPA). The report anticipates that updated guidelines will require cables to exhibit superior flame-retardant properties and reduced smoke emission levels. This push for enhanced safety is driven by ongoing concerns about fire hazards in commercial and residential buildings, underscoring the need for construction professionals to stay abreast of these developments when selecting appropriate electrical cable types.

Moreover, sustainability metrics are increasingly being integrated into regulatory standards, as noted in the World Green Building Council’s latest report. In 2025, projects will likely demand cables that meet specified life cycle assessment criteria, encouraging the use of recyclable and environmentally friendly materials. This shift highlights the growing importance of eco-conscious choices in electrical infrastructure, prompting the need for constructors to evaluate not only the technical performance of cables but also their ecological impact throughout their lifespan.