Choosing the right power cable is essential for ensuring the safety, efficiency, and longevity of your electrical systems. With the increasing complexity of electrical requirements in homes and businesses, understanding the various types of power cables available has become more crucial than ever. Power cables are designed to convey electricity from one point to another and come in a wide range of specifications to meet diverse operational demands. This introduction will guide you through the fundamental considerations when selecting the ideal power cable for your needs.

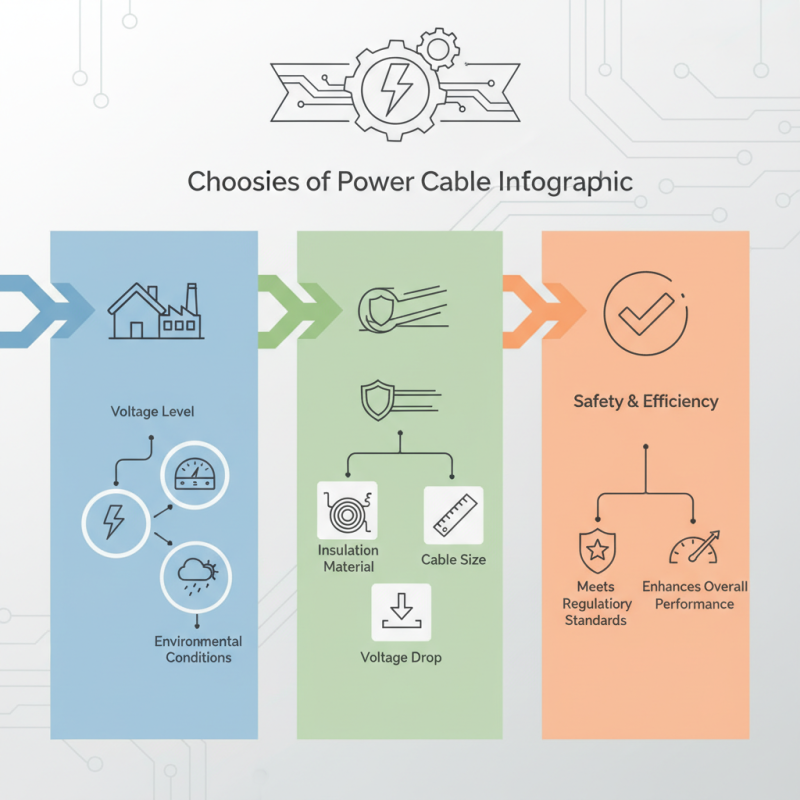

The first step in choosing the right power cable involves assessing the specific requirements of your electrical project, such as the voltage level, current capacity, and environmental conditions. Different applications may require distinct cable types, whether for residential use, industrial settings, or outdoor installations. Furthermore, factors like insulation material, cable size, and voltage drop should also be taken into account to ensure safety and functional adequacy. By gaining a clear understanding of these elements, you can make informed decisions and select a power cable that not only meets regulatory standards but also enhances the overall performance of your electrical system.

When considering the right power cable for your electrical needs, it is crucial to understand the various types available on the market. Power cables are typically categorized based on their construction and application. Two of the most common types are PVC insulated cables and XLPE insulated cables. According to the International Electrotechnical Commission (IEC), PVC cables are often favored for their flexibility and cost-effectiveness, making them suitable for applications in residential and commercial buildings. Contrarily, XLPE cables, known for their higher thermal resistance and environmental durability, are increasingly used in industrial settings, particularly for high-voltage applications.

Moreover, cables are also classified based on their conductor materials - primarily copper and aluminum. Data from the Copper Development Association highlights that copper cables boast superior conductivity, which translates to lesser energy losses over long distances. They are particularly recommended for power distribution systems. On the other hand, aluminum cables are lighter and less expensive, making them a popular choice for overhead power lines. However, due to higher resistivity, they typically require larger wire sizes to carry the same current as copper. Understanding these factors is essential in making an informed decision that meets specific electrical demands while optimizing safety and efficiency.

When selecting the appropriate power cable for your electrical needs, evaluating voltage and current requirements is crucial. The voltage rating of a cable indicates the maximum voltage it can safely handle without risk of failure. It's essential to assess the voltage supplied by your electrical system and match it with a cable that has an adequate voltage rating to prevent overheating or insulation breakdown. For instance, if your device requires a supply of 120V, using a power cable rated for 300V or more ensures an extra margin of safety, accommodating any potential fluctuations in voltage.

Current requirements are equally important as they determine the size and gauge of the power cable. Each cable gauge has a specific ampacity, which denotes the maximum current it can carry without overheating. To select the appropriate gauge, calculate the total current load of all connected devices and ensure that the chosen cable can handle this load efficiently. Additionally, consider the length of the cable run, as longer distances may require thicker cables to minimize voltage drop and ensure optimal performance. Balancing both voltage and current requirements will lead to a safe and effective electrical setup tailored to your needs.

This chart illustrates the current capacity (in Amperes) of different power cable wire gauges. Selecting the appropriate cable gauge is crucial to ensure safety and efficiency in electrical setups.

When selecting a power cable for your electrical needs, one of the most critical aspects to consider is the cable insulation rating. Insulation materials play a crucial role in protecting the conductive wires within the cable from environmental factors and electrical faults. Various insulation materials are designed to withstand different temperatures, voltages, and potential hazards, which makes it essential to choose the right type based on your specific applications. For instance, some insulation types are more suitable for indoor use, while others can endure harsh outdoor conditions without deteriorating.

Understanding the insulation rating, often denoted by a code such as THHN or XHHW, provides insight into the cable's performance and safety capabilities under various conditions. These ratings indicate factors such as temperature tolerance, moisture resistance, and flammability levels. Higher-rated insulation materials generally offer better protection and longevity, especially in applications that involve exposure to heat or chemicals. By carefully assessing these ratings, you can ensure that the power cable you choose will not only meet your electrical requirements but also contribute to the overall safety of the installation.

| Cable Type | Insulation Rating | Temperature Range (°C) | Application | Maximum Voltage (V) |

|---|---|---|---|---|

| PVC Cable | 60/70 °C | -10 to 70 | General Wiring | 300 |

| XLPE Cable | 90 °C | -30 to 90 | Power Distribution | 600 |

| Rubber Cable | 60 °C | -20 to 60 | Flex Applications | 450 |

| Teflon Cable | 200 °C | -60 to 200 | High-Frequency | 600 |

| Silicone Cable | 180 °C | -60 to 180 | Harsh Environments | 600 |

When selecting the appropriate power cable for any electrical installation, two critical considerations are cable length and flexibility. The National Electrical Code (NEC) emphasizes that the length of the cable can greatly affect both voltage drop and power efficiency. For instance, a cable that is excessively long may suffer from significant voltage drops, particularly in installations exceeding 100 feet. According to a report by the Institute of Electrical and Electronics Engineers (IEEE), voltage drop can be around 3% for longer runs, which not only impacts performance but can also lead to increased operational costs over time.

Flexibility is another vital factor in choosing the right power cable, especially in applications where movement or reconfiguration is common. A study conducted by the European Committee for Electrotechnical Standardization (CENELEC) suggests that using more flexible cables can reduce wear and tear in dynamic environments, thus prolonging the cable's lifespan and reliability. For installations in tight spaces or where bends are frequent, selecting cables with improved flexibility ratings is essential. This ensures that the installation remains safe and effective, minimizing the risk of damage and reducing maintenance needs.

In summary, understanding both the necessary cable length and the desired flexibility for specific applications helps optimize performance and ensures compliance with electrical standards. By consulting industry standards and guidelines, electrical installers can make informed decisions that enhance both safety and efficiency in their electrical systems.

When selecting the right power cable for your electrical needs, cost considerations and quality factors play a vital role in the decision-making process. According to a market analysis report by Mordor Intelligence, the global power cable market is projected to reach $250 billion by 2025, signifying the increasing demand and the variety of options available. Understanding the balance between cost and quality can lead to better long-term investments for both residential and commercial applications.

Cost is often the first factor to consider, but it is crucial to note that the cheapest option may not always be the best. The National Fire Protection Association (NFPA) states that improper cable selection can lead to electrical failures and potential fire hazards. Investing a bit more upfront for high-quality cables that offer better insulation, conductivity, and durability can save significant costs associated with repairs and replacements down the line. A report from Research and Markets suggests that high-quality cables have the potential to last up to 40% longer than their lower-cost counterparts, making them a more economical choice in the long run.

Quality factors like material composition, insulation type, and environmental ratings should be meticulously evaluated. For instance, copper cables, while more expensive than aluminum, possess superior conductivity, which results in lower energy losses. Meanwhile, cables with higher temperature ratings can withstand extreme conditions without degrading, enhancing safety and reliability. Prioritizing these quality indicators, while keeping budget constraints in mind, can facilitate a more informed decision that ensures effective and safe electrical performance.