In the ever-evolving landscape of electrical efficiency, selecting the right Power Wire is critical to optimizing performance and safety in various applications. As we approach 2025, industry experts are emphasizing the importance of diligent selection processes, which can immensely influence energy consumption and operational costs. A recent report from the International Electrical Safety Association has highlighted that inefficient wiring could account for up to 30% of energy losses in electrical systems—a statistic that underscores the need for informed choices in Power Wire delivery systems.

Renowned electrical engineer, Dr. James Hartman, posits that "the choice of Power Wire can mean the difference between a thriving electrical system and one plagued with inefficiencies." With the industry rapidly advancing towards smarter and more sustainable solutions, the significance of proper Power Wire selection cannot be overstated. By understanding the various types available, their specific applications, and the underlying technology, users can ensure they maximize both performance and electrical efficiency in 2025 and beyond.

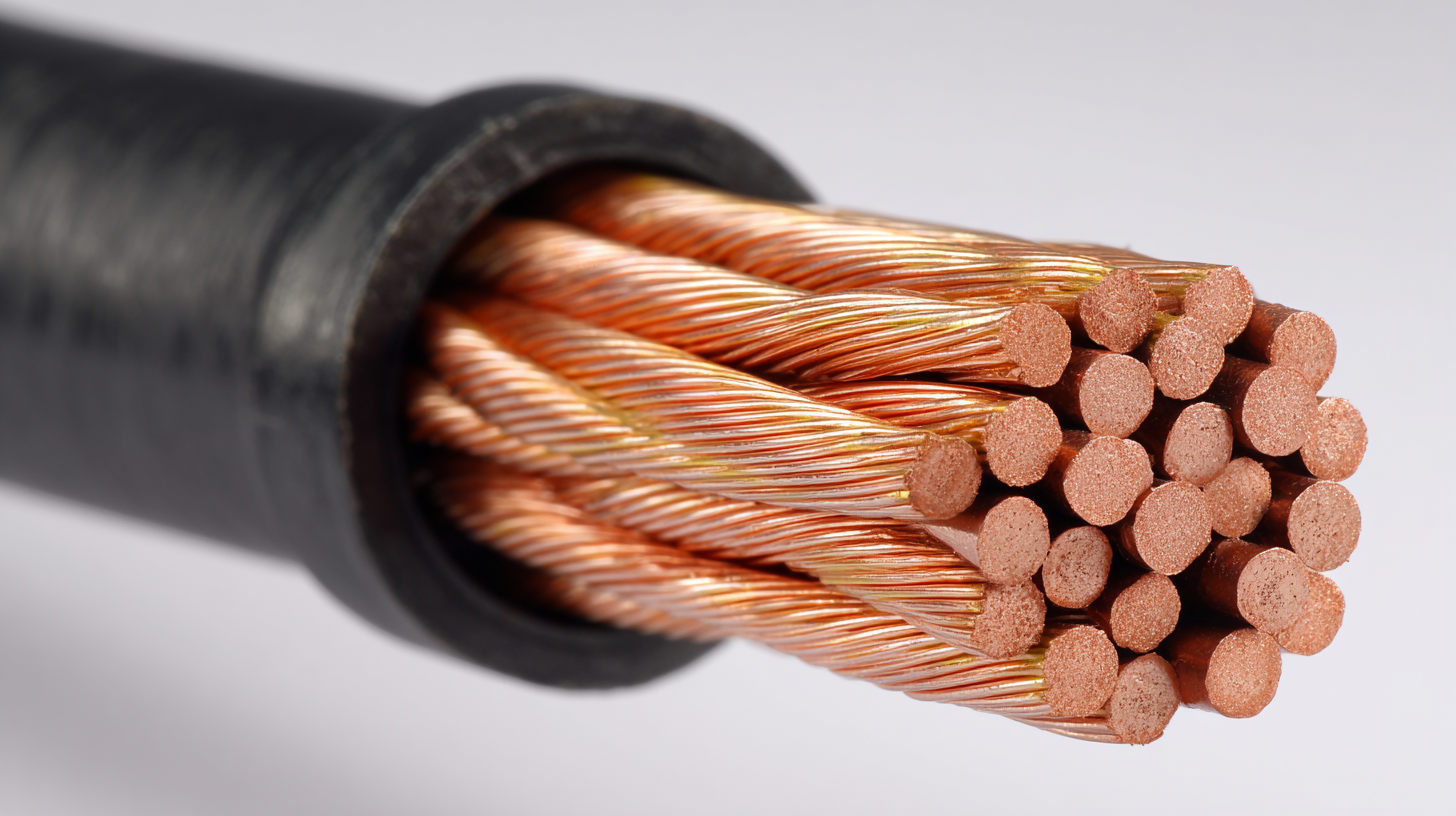

When selecting the best power wire for optimal electrical efficiency, understanding electrical resistance is crucial. Electrical resistance affects how much energy is lost as heat during power transmission. A wire's resistance depends on its material, length, and cross-sectional area. Conductors like copper and aluminum are popular choices due to their low resistance, allowing for efficient energy transfer. However, longer wires experience higher resistance, leading to more significant energy loss, which can compromise system efficiency.

Choosing the appropriate wire gauge is essential to mitigate resistance. Thicker wires have a lower resistance per unit length, making them more efficient for longer distances. Additionally, considering the operating temperature is vital, as heating can increase resistance, further impacting efficiency. For optimal performance, it is also necessary to evaluate the wire's insulation type and its suitability for specific applications, ensuring that it can handle the expected current without overheating. By prioritizing these factors, one can significantly enhance electrical efficiency and performance in any power system.

When it comes to electrical efficiency, choosing the right wire gauge is crucial. Thicker wires, typically referred to as lower gauge wires, have a distinct advantage in reducing energy loss due to their ability to carry higher current with less resistance. This is particularly important in long-distance electrical applications where resistance can cause significant voltage drops, leading to inefficiencies and potential overheating.

Using thicker cables helps minimize the resistive losses in electrical systems. For instance, when electricity flows through a wire, some energy is inevitably lost as heat, proportional to the wire's resistance. By opting for a thicker wire, homeowners and electricians can ensure that the amount of energy wasted in this manner is significantly lowered. Ultimately, this not only enhances efficiency but can also lead to cost savings over time, as reduced energy loss translates into lower electricity bills and improved performance of electrical systems.

When it comes to choosing the best power wire for optimal electrical efficiency, the materials used play a crucial role. Copper has long been regarded as the king of conductors, renowned for its excellent electrical conductivity, durability, and resistance to corrosion. This metal not only facilitates efficient electrical flow but also plays a significant role in minimizing energy losses in wiring systems. As demands for improved energy efficiency grow, copper remains a top choice for electrical applications due to its proven performance over more than a century.

However, aluminum has emerged as a competitive alternative, especially in large-scale applications where weight and cost are critical factors. Aluminum wires are lighter and less expensive, which can make them advantageous in specific situations, such as in overhead power lines. While aluminum is not as conductive as copper, advancements in technology have improved its performance, allowing it to hold its ground in various electrical applications. Ultimately, the decision between copper and aluminum should be guided by the specific requirements of the project, weighing factors such as budget, installation environment, and long-term efficiency.

This chart illustrates the electrical efficiency of copper and aluminum as power wire materials. Copper exhibits a significantly higher efficiency percentage compared to aluminum, making it the preferred choice for optimal electrical performance.

When selecting power wires, understanding temperature ratings is crucial for ensuring both safety and efficiency. Proper temperature ratings indicate how much heat a wire can withstand before its insulation degrades, which is vital for preventing electrical failures and potential hazards. According to the National Electrical Code (NEC), wires must be rated for at least 60°C for residential applications, but higher ratings might be necessary depending on the installation conditions. For instance, in industrial settings where higher temperatures are prevalent, selecting wires with ratings of 75°C to 90°C is essential to maintain reliability and compliance with safety standards.

Tips: Always check the ambient temperature of the environment where the wires will be installed, as it can significantly impact performance. Employing wires rated for higher temperatures can provide a safety margin, helping to prevent insulation breakdown over time.

Furthermore, the electrical load that wires will carry plays a vital role in determining the appropriate temperature rating. The American Wire Gauge (AWG) system provides guidelines on load capacity, recommending larger diameter wires for higher currents, which also helps in managing heat generation. Critical data from the 2023 IEC International Standards shows that neglecting these factors can lead to a 30% increase in energy loss, underscoring the importance of thorough assessment before making your choice.

Tips: Always calculate the total load and consider using wires that exceed the minimum requirements to enhance performance and longevity.

When selecting the best power wire for optimal electrical efficiency, understanding the environmental factors impacting installation conditions is crucial. Recent studies emphasize the importance of outdoor space design, particularly in climates such as China’s subtropical regions, where installation in hot-humid conditions can significantly affect performance. For instance, a study indicated that thermal expansion and contraction due to temperature fluctuations can lead to increased resistive losses in power wires, thereby reducing overall electrical efficiency by approximately 10-15% in certain installations.

Furthermore, the correlation between work environments and system performance cannot be overlooked. Research reveals that inadequate environmental conditions can lead to suboptimal performance of electrical materials. For instance, factors such as humidity and temperature variation play critical roles in material degradation and conductivity. It is reported that utilizing wires with higher resistance to environmental stressors can extend service life by up to 20% while maintaining efficiency. As such, selecting power wires tailored to specific environmental conditions can enhance electrical efficiency and reliability in diverse installations.