In today's fast-paced technological landscape, selecting the right components for your project is crucial for achieving the desired performance and efficiency. Among these components, flat cables play a significant role, acting as conduits for electrical signals in various applications ranging from consumer electronics to industrial machinery. With their unique design and versatility, flat cables offer numerous advantages, including space-saving properties and ease of installation. However, not all flat cables are created equal, and the selection process can be daunting, especially with the array of options available on the market.

Understanding the specific needs of your project is essential when choosing the appropriate flat cable. Factors such as conductor material, insulation type, length, and application environment must be carefully considered to ensure optimal performance and reliability. This guide will delve into the critical aspects of flat cable selection, helping you navigate through the complexities of making an informed decision that aligns with your project requirements. Whether you are working on a small DIY task or a large-scale industrial project, knowing how to choose the right flat cable can significantly impact your success and efficiency.

When selecting the appropriate flat cable for your project, understanding the various types of flat cables and their specific applications is essential. Flat cables, characterized by their thin and flexible structure, come in multiple configurations, including ribbon cables, flat flexible cables (FFC), and flat printed circuit cables (FPC). Ribbon cables, often utilized in computer systems, consist of multiple conductors running parallel to one another, allowing for efficient signal transmission in tight spaces. They are widely favored in applications that require high-density connections, such as inside desktop computers or other electronic devices.

Flat flexible cables (FFC) and flat printed circuit cables (FPC) are advantageous in applications requiring intricate routing and compact design. FFCs are typically used in consumer electronics, like cameras and smartphones, due to their lightweight nature, while FPCs offer the added benefit of being more durable against bending and twisting, making them ideal for applications in automotive and medical devices. Understanding the specific requirements of your project—such as the environment the cable will operate in, its flexibility, and electrical performance—will help you choose the right flat cable type to ensure reliability and efficiency in your application.

This bar chart illustrates the monthly usage frequency of different flat cable types. Understanding these metrics can help you choose the right flat cable for your specific project needs.

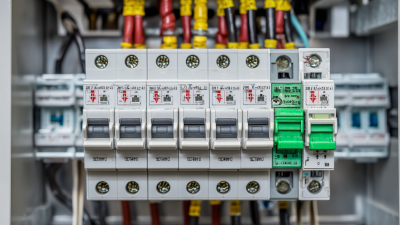

When selecting a flat cable for your project, several key factors should guide your decision-making process. First, consider the cable's application and environment. Flat cables are often used in tight spaces, where flexibility and flatness become critical considerations. Assess the mechanical stress the cable will endure, including bending, twisting, and movements, to ensure it can withstand the operational demands of your project.

Another vital aspect is the electrical specifications of the cable. This includes the voltage ratings, current capacity, and the type of insulation material used. Different projects may require specific ratings to ensure safety and functionality. It's also essential to factor in the cable's resistance to interference, especially in applications where data integrity is paramount. Lastly, think about the temperature range in which the cable will operate, as extremes beyond rated limits can lead to performance issues or failures. By carefully evaluating these factors, you can make an informed choice that meets your project's unique requirements.

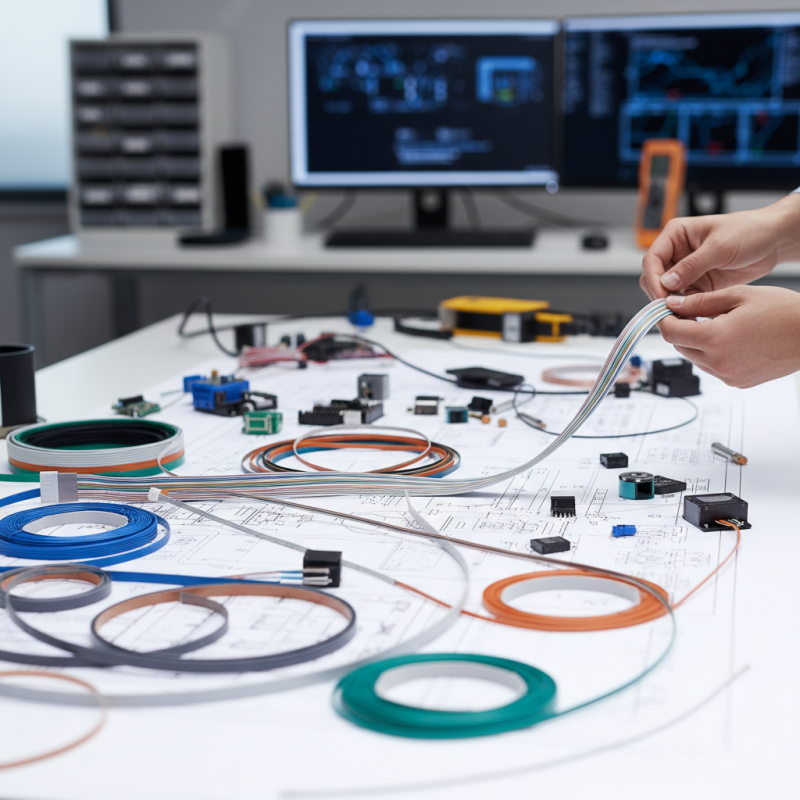

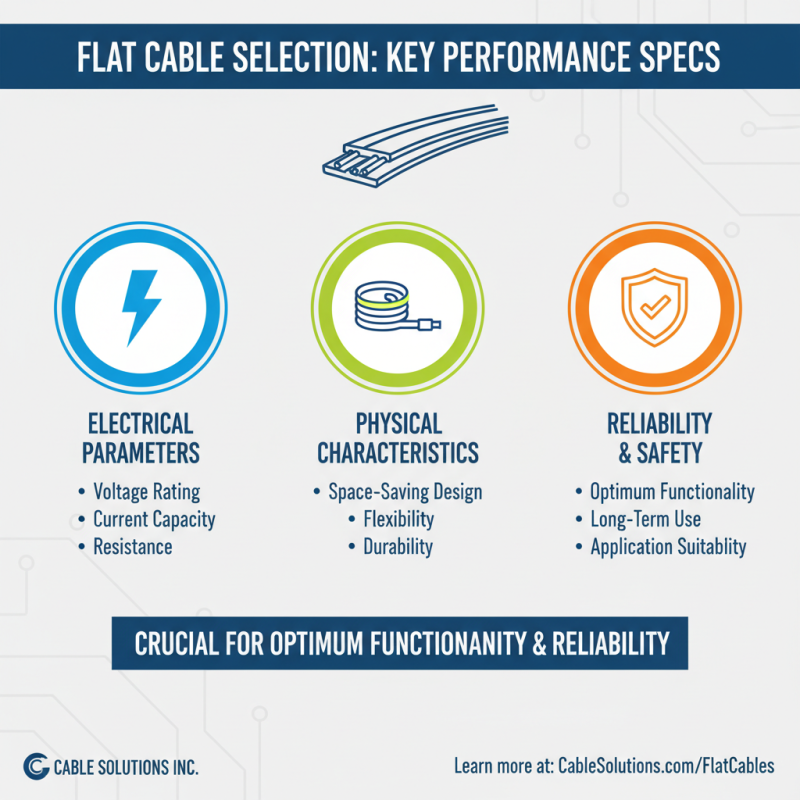

When selecting flat cables for your project, evaluating performance specifications is crucial for ensuring optimum functionality and reliability. Flat cables are typically chosen for their space-saving characteristics and flexibility, which makes them ideal for applications in tight spaces or where traditional round cables may not fit. Key performance specifications to consider include electrical parameters such as voltage rating, current carrying capacity, and resistance, as these factors directly influence the cable's efficiency and safety in use.

In addition to electrical characteristics, other important specifications include mechanical properties and environmental resistance. The mechanical flexibility of the cable is particularly important where it will be subjected to repeated bending or movement. Furthermore, assess the environmental conditions the cable will encounter, such as exposure to moisture, heat, or chemicals, as these factors will affect material selection and overall durability. Understanding these various performance specifications will enable you to better align the flat cable choice with the specific demands of your project while ensuring long-term performance and reliability.

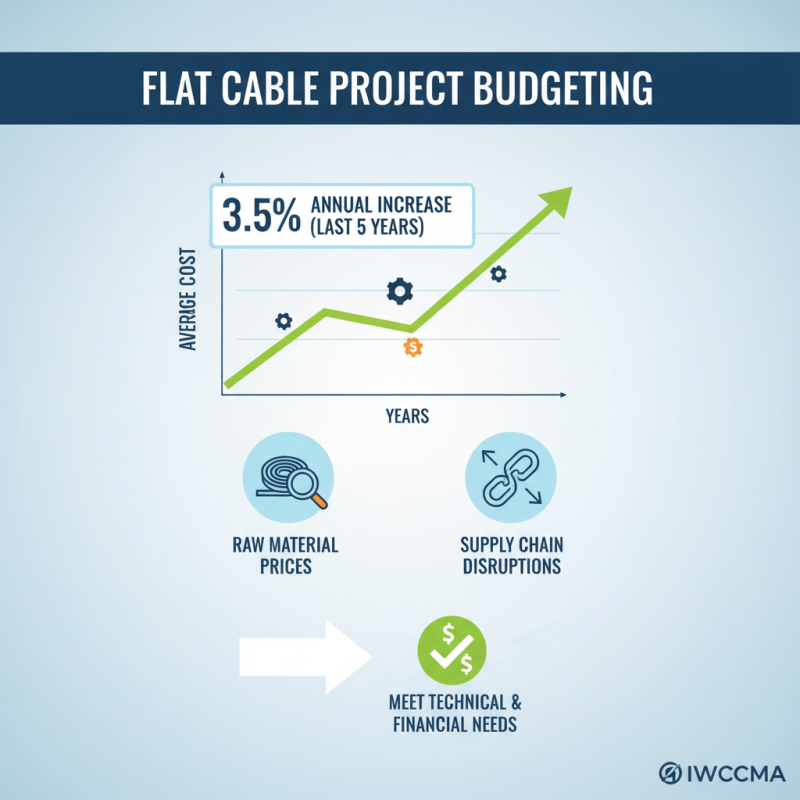

When choosing the right flat cable for a project, it's vital to consider the cost and budget implications that come with various cable types. According to a recent report by the International Wire and Cable Manufacturers Association, the average cost of flat cables has experienced a steady increase of about 3.5% annually over the past five years, primarily due to rising raw material prices and supply chain disruptions. Understanding these trends can help project managers anticipate expenses and budget accordingly, ensuring that they select a cable that not only meets their technical requirements but also aligns with their financial constraints.

Moreover, it is essential to conduct a thorough cost-benefit analysis when selecting flat cables. While some high-performance cables may present a higher upfront cost, their durability and lower maintenance needs can lead to significant savings over the project's lifespan. A study by the IEEE suggests that investing in higher-quality cabling can reduce the total cost of ownership by up to 15% over ten years, making it a prudent choice for many projects. By carefully assessing both the immediate costs and long-term benefits, project teams can make informed decisions that balance performance and financial viability.

When it comes to installing flat cables, adhering to best practices is essential for ensuring both performance and longevity. According to the International Electrotechnical Commission (IEC), proper installation techniques can reduce the risk of cable damage by up to 30%. One critical aspect is maintaining the appropriate bend radius during installation; exceeding the recommended limits can lead to stress on the cable, resulting in signal degradation or even failure. Additionally, using the correct cable management systems, such as cable trays and clips, can help avoid tangling and excessive strain that contribute to early wear.

In terms of maintenance, routine inspections play a vital role in the longevity of flat cables. The National Electrical Manufacturers Association (NEMA) recommends scheduling evaluations at least biannually, focusing on visible signs of wear, such as abrasions, cuts, or discoloration. Furthermore, environmental factors, such as humidity and temperature fluctuations, should be monitored. For example, cables exposed to high moisture levels can lead to corrosion and electrical issues, highlighting the importance of choosing cables rated for specific environmental conditions. Implementing these best practices can significantly enhance performance and reliability throughout the lifecycle of the flat cable installation.

| Dimension | Description | Recommended Application | Maintenance Tip |

|---|---|---|---|

| Thickness | The overall thickness of the cable. | Ideal for compact installations. | Check periodically for wear and tear. |

| Width | The width of the cable designed for installation. | Suitable for tight spaces and routing. | Ensure proper alignment during installation. |

| Material | Type of insulation and conductor materials. | For environments with varying temperatures. | Clean regularly to prevent corrosion. |

| Current Rating | Maximum current the cable can handle. | Used in high power applications. | Monitor for heat build-up during operation. |

| Flexibility | Ability of the cable to bend without breaking. | Best for movable or dynamic setups. | Avoid sharp bends during use to maintain integrity. |