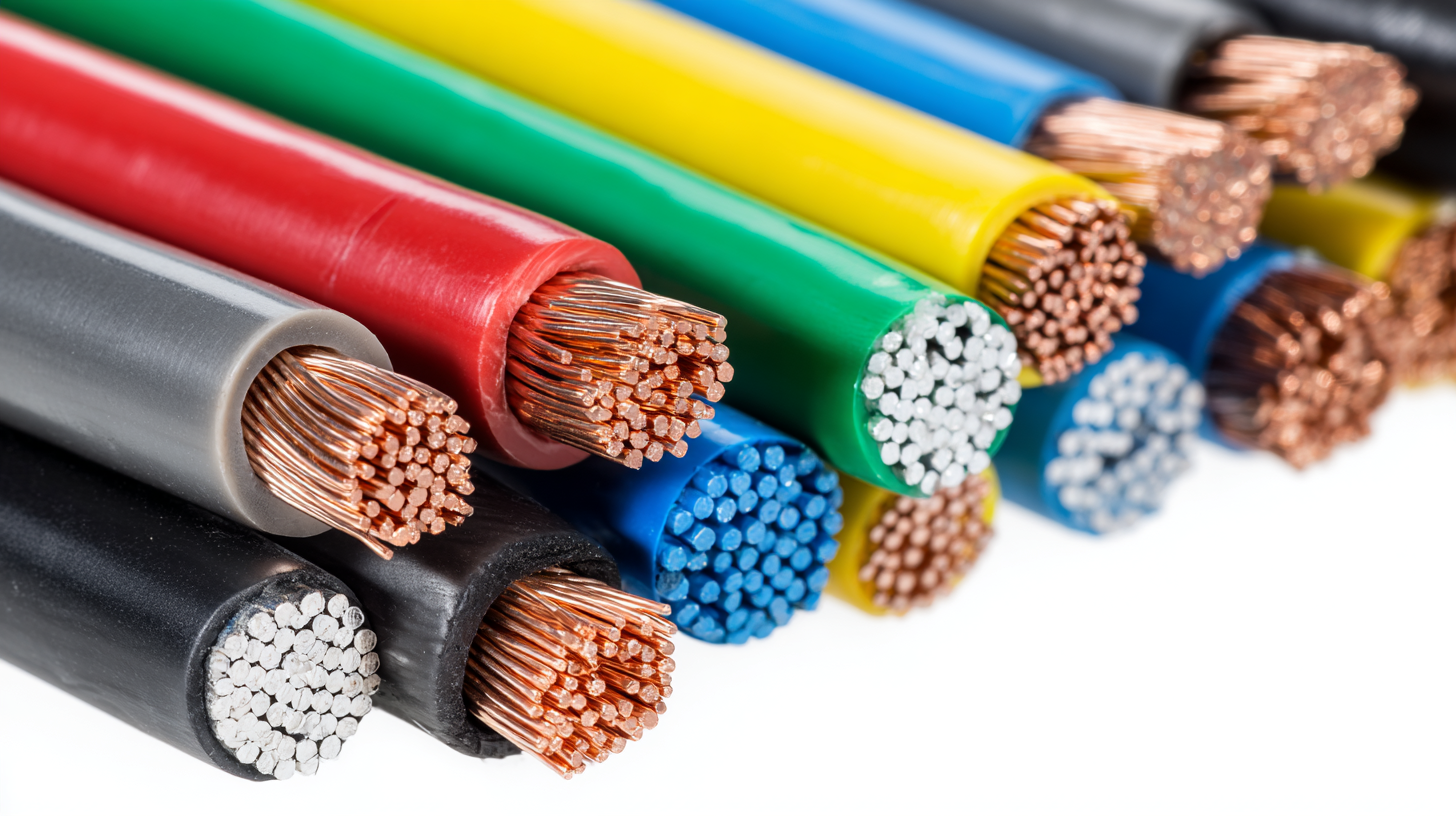

When embarking on home projects, one of the most critical considerations is the type of Electric Wire you choose. With a plethora of options available, understanding the alternatives can significantly impact both the safety and efficiency of your electrical installations. Whether you're undertaking a simple DIY task or a more complex renovation, selecting the right Electric Wire involves evaluating factors such as gauge, insulation type, and application-specific requirements.

This blog will guide you through the various alternatives available in the market, helping you to make informed decisions tailored to your specific needs. By delving into the characteristics and benefits of different Electric Wire types, you can ensure your home projects are not only successful but also up to code and safe for long-term use.

When embarking on home projects, one of the most critical considerations is the type of Electric Wire you choose. With a plethora of options available, understanding the alternatives can significantly impact both the safety and efficiency of your electrical installations. Whether you're undertaking a simple DIY task or a more complex renovation, selecting the right Electric Wire involves evaluating factors such as gauge, insulation type, and application-specific requirements.

This blog will guide you through the various alternatives available in the market, helping you to make informed decisions tailored to your specific needs. By delving into the characteristics and benefits of different Electric Wire types, you can ensure your home projects are not only successful but also up to code and safe for long-term use.

When undertaking home electrical projects, understanding the different types of electric wires is crucial for safety and efficiency. The National Electrical Manufacturers Association (NEMA) highlights that the most common types of wires used in residential applications include

non-metallic sheathed wire (NM), also known as Romex, and

armored cable (AC). NM wire is typically suitable for indoor use, providing flexibility and ease of installation, whereas AC cable offers additional protection from physical damage, making it ideal for areas prone to moisture or exposure.

Another important aspect to consider is the wire gauge, which is a critical factor in ensuring that the electrical system can handle the intended load. According to the National Fire Protection Association (NFPA), using the appropriate wire gauge is essential to prevent overheating and potential fires.

For instance, 12-gauge wire is commonly used for lighting circuits and outlets, while 14-gauge wire may be adequate for light fixtures.

Electricians recommend assessing the specific requirements of each project, such as the planned wattage and the distance from the power source, to select the best wire type and gauge that meets the current

National Electrical Code (NEC) standards.

When selecting electric wire for your home projects, there are several key factors to consider to ensure safety and efficiency. Firstly, understand the wire gauge or thickness. A lower gauge number indicates a thicker wire that can handle more current, making it essential to match the gauge to the specific requirements of your project. For instance, installations like heavy appliances may require 10 or 12-gauge wire, while lighting circuits might only need 14-gauge wire.

Another critical factor is the type of insulation used on the wire. Different environments require different types of insulation to prevent damage and ensure safe operation. For indoor projects, look for non-metallic (NM) sheathed cable, which is versatile and easy to work with. Conversely, if you are installing wire outdoors or in damp areas, ensure that it is rated for such use, like UF (underground feeder) cable.

Another critical factor is the type of insulation used on the wire. Different environments require different types of insulation to prevent damage and ensure safe operation. For indoor projects, look for non-metallic (NM) sheathed cable, which is versatile and easy to work with. Conversely, if you are installing wire outdoors or in damp areas, ensure that it is rated for such use, like UF (underground feeder) cable.

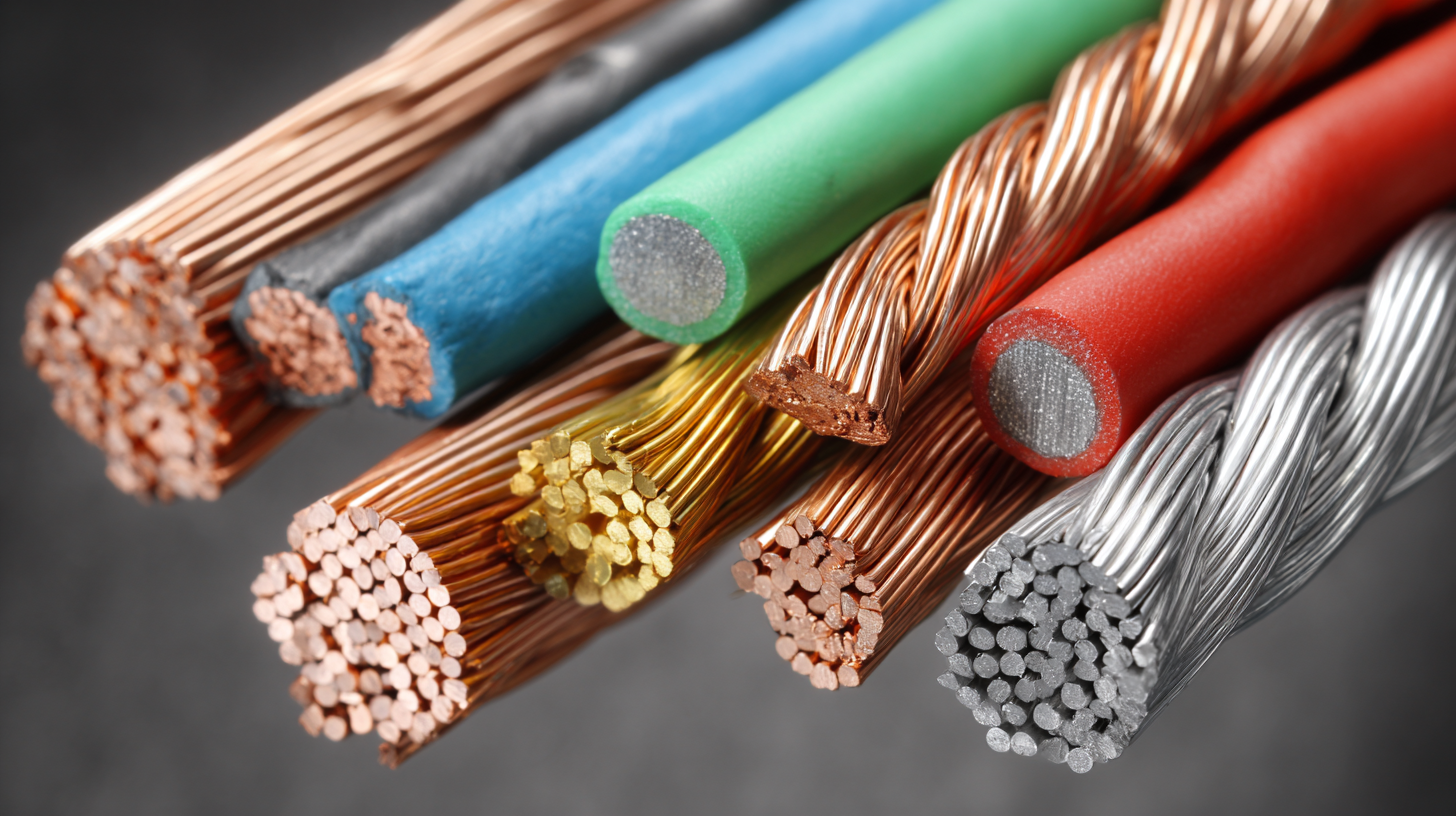

Finally, consider the wire material. Copper and aluminum are the two most common options, with copper being more conductive and resistant to corrosion. Copper wires are typically preferred for residential applications due to their durability and efficiency. Always check local electrical codes before starting your project to ensure compliance and safety.

When choosing electric wire for your home projects, understanding safety ratings and standards is crucial. These ratings, often indicated by labels such as UL (Underwriter Laboratories) or NEC (National Electrical Code), are designed to ensure that the wire can safely handle the electrical load required for your specific applications. A wire with appropriate ratings not only ensures compliance with local building codes but also minimizes risks such as electrical fires or short circuits.

It is essential to pay attention to these ratings, as using substandard wire can lead to hazardous situations that compromise your home’s safety.

Moreover, safety standards often dictate the type of insulation and its resistance to environmental factors. For instance, wires used in moist or outdoor environments should have insulation that is rated for those specific conditions, such as THHN or UF wire. Choosing wire that meets these safety standards guarantees that your home projects are not just functional, but also safe. Familiarizing yourself with these specifications empowers you to make informed decisions, ensuring that your electrical installations are durable and secure for years to come.

When it comes to selecting the right electric wire for home projects, understanding wire gauge is crucial. The American Wire Gauge (AWG) system helps determine the thickness of wiring, impacting its ampacity or the amount of current it can safely carry. For instance, a 14 AWG wire can typically handle up to 15 amps, making it suitable for general lighting, while 12 AWG can support up to 20 amps, often used for kitchen and bathroom circuits. Choosing the wrong gauge can lead to overheating and potential fire hazards, as highlighted by the National Fire Protection Association, which reports that nearly 30% of electrical fires in homes are related to faulty wiring.

Additionally, the wire gauge affects voltage drop, an essential factor in ensuring your devices operate efficiently. For runs longer than 100 feet, a thicker wire—like 10 AWG—may be necessary to keep voltage drop within acceptable limits of 3% or less, according to the National Electrical Code (NEC). Neglecting the gauge on longer runs can lead to diminished performance of appliances and electronic devices. Therefore, it’s vital to choose the appropriate wire gauge in relation to the distance and electrical load requirements to ensure safety and efficiency in your home projects.

When it comes to selecting the best electric wire for home projects, the choice between copper and aluminum wires is crucial. Copper wires have long been regarded as the gold standard in electrical applications, primarily due to their excellent conductivity and resistance to corrosion. According to the National Electrical Contractors Association (NECA), copper wires can conduct electricity at a higher efficiency than aluminum, making them ideal for high-demand circuits. Copper’s superior conductance means that it can transmit electricity over longer distances without significant voltage drop, ensuring that your electrical systems function optimally.

On the other hand, aluminum wires provide a cost-effective alternative that has gained popularity in residential projects. The U.S. Department of Energy notes that aluminum wiring is approximately 30% lighter than copper, which can facilitate installation and reduce labor costs. However, one must consider that aluminum has a higher coefficient of thermal expansion, which can lead to connections loosening over time and potentially create hazards if not properly managed. Furthermore, aluminum is generally more susceptible to oxidation, which can affect conductivity. Evaluating these pros and cons is essential for homeowners to make informed decisions about their electrical wiring needs, ensuring both safety and efficiency in their projects.