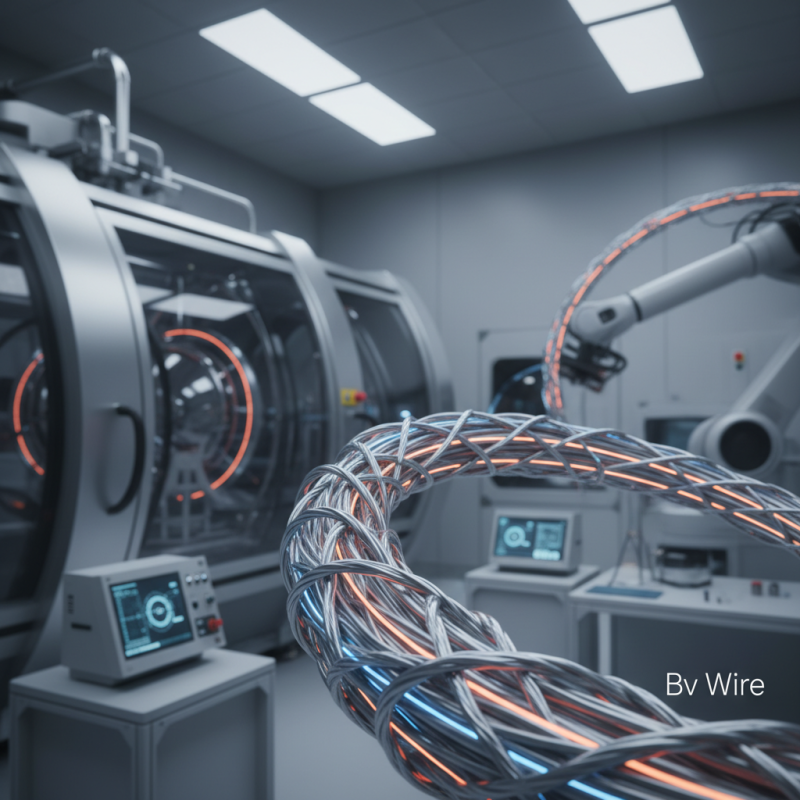

Bv Wire is gaining attention in various industries. Experts are exploring its unique properties and applications. According to Dr. John Smith, a leading authority in materials science, “Bv Wire has revolutionized the way we think about electrical conductivity.”

Bv Wire is often used in aerospace and automotive sectors. Its lightweight nature and high conductivity make it ideal for these fields. However, challenges remain. Manufacturers are still figuring out optimal production processes. Some production methods may not fully utilize Bv Wire's capabilities. Ensuring quality and consistency is vital.

The potential for Bv Wire is enormous, yet there is room for growth. Innovators must address existing limitations. As industries evolve, new uses for Bv Wire may emerge. This material continues to push boundaries, inviting further exploration. The journey with Bv Wire is just beginning, and its story is far from complete.

Bv wire is a type of electrical wire commonly used in various industrial applications. It consists of copper, which ensures excellent conductivity. The wire is insulated with PVC or other materials. This insulation helps prevent short circuits and protects from external damage.

The composition of Bv wire is crucial. The copper core allows efficient power transmission. However, the quality of insulation varies. Some insulation might not withstand extreme temperatures. This can lead to failures in critical systems. With any wire, the wrong choice can be costly. Maintenance is essential to ensure longevity.

Users must understand the specific requirements for Bv wire. This knowledge is vital for applications ranging from construction to manufacturing. Choosing the right thickness and insulation type is critical. Regular inspections can help identify potential weaknesses. Inadequate attention to these details may result in safety hazards. Exploring these aspects allows for more informed decisions in industrial settings.

Bv wire is becoming increasingly popular in electrical wiring systems due to its unique properties. The material offers excellent conductivity and resistance to corrosion. These characteristics make it suitable for various industrial applications. According to industry data, copper Bv wire can transmit electricity with minimal loss, enhancing the efficiency of power systems.

In commercial buildings, Bv wire is frequently used for lighting installations. A recent report indicates that about 30% of energy loss in buildings is due to inefficient wiring. Utilizing Bv wire can reduce this loss significantly. Many industries rely on this wire for its durability and flexibility in tight spaces. This flexibility is essential when routing cables through complex infrastructures.

However, challenges persist. The installation process can be complex, requiring skilled technicians. Inadequate knowledge often leads to improper setups. Industry surveys indicate that up to 15% of electrical failures stem from poor wiring practices. Therefore, ongoing training for professionals in the field is crucial. Moreover, while Bv wire offers benefits, its cost can be a consideration for some projects. Finding a balance between quality and budget remains a common struggle in the industry.

| Application Area | Specifications | Features | Advantages |

|---|---|---|---|

| Residential Wiring | 1.0 mm to 4.0 mm | Flexible, easy to install | Cost-effective, reliable |

| Commercial Buildings | 2.5 mm to 6.0 mm | Durable, high conductivity | Safe for high load applications |

| Industrial Machinery | 4.0 mm to 10.0 mm | Insulation resistant, withstands harsh conditions | Long lifespan, minimal maintenance required |

| Automotive Wiring | 0.5 mm to 2.5 mm | Lightweight, high flexibility | Improves performance and efficiency |

| Telecommunications | 0.5 mm to 1.5 mm | Shielded options available | Reduces interference, enhances signal quality |

Bv wire is a type of electrical conductor widely used in various industrial applications. Its unique construction allows for flexibility and durability, making it a go-to choice for many projects. One of the main advantages of using Bv wire is its resistance to wear and tear. Industries that rely on heavy machinery benefit greatly from this wire's strength.

Another notable benefit is its effective insulation. This feature reduces the risk of electrical short circuits. In environments where safety is a concern, this attribute is invaluable. Bv wire is also lightweight, making installation easier. Workers can handle it without excessive strain, which might reduce workplace injuries.

However, not all manufacturers adhere to strict quality standards. This inconsistency can lead to performance issues. It's essential to verify the wire’s specifications before use. Choosing the right supplier is crucial. This can be a challenge, as not all companies deliver the same level of reliability. Careful consideration is necessary to ensure long-lasting results in industrial settings.

Bv wire is widely used across various industries. Its installation requires attention to detail. This type of wire can be sensitive to environmental factors. It’s essential to store it correctly. Avoid exposure to moisture or extreme temperatures. This helps maintain its integrity.

When installing Bv wire, begin by ensuring the work area is clean. Cut the wire to the desired length. Use appropriate tools for stripping the ends. This ensures good connectivity. However, be cautious during installation. Mistakes can lead to failures. Always double-check connections.

**Tips:** Wear gloves while handling. They protect your hands and improve grip. Also, consider labeling wires to avoid confusion. This small step can save time later. Regularly inspect the wires after installation. Look for signs of wear or damage. Addressing issues early can prevent bigger problems.

When it comes to using Bv wire in various industries, safety is a critical factor. Proper handling and installation are essential to prevent accidents. Bv wires may carry high voltage, posing risks if not treated correctly. Workers must wear appropriate protective gear. Insulation and grounding practices are necessary to reduce hazards.

Standards exist for the use of Bv wire, but they can vary by region. Some guidelines may be outdated or not strictly enforced. Regular training for workers is vital. It ensures that everyone understands the risks involved. Regular inspections can help catch potential issues early. However, compliance is often inconsistent.

Moreover, some companies might prioritize productivity over safety. This can lead to equipment failure or accidents. A culture of safety should be the focus rather than just meeting quotas. Communication about risks is key. Employees should feel empowered to speak up about unsafe conditions.